Emergency Repair Solutions for Conveyor Belts: Fast and Effective Methods | Belt Patch, Belt Sealant | Airform Conveyor Belt Solutions

Emergency Repair Solutions

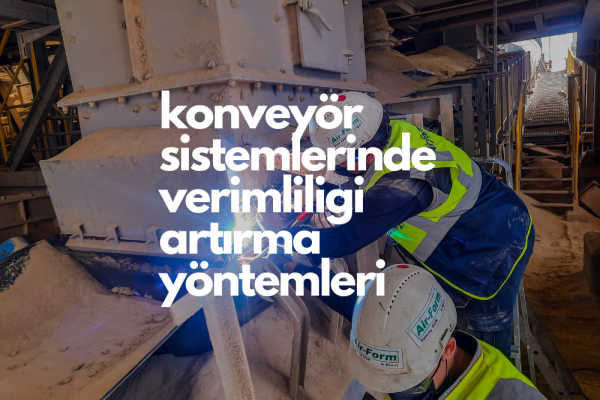

Conveyor belt systems are a critical part of production and logistics processes. However, even the most durable systems can experience wear and tear and damage from time to time. In such cases, fast and effective repair solutions are crucial to ensure production processes remain uninterrupted. At AirForm, we offer a variety of conveyor belt repair solutions that are perfect for these emergencies.

Speed and Reliability in Belt Repair:

A conveyor belt stoppage on a production line can lead to unexpected costs and disruptions to production processes. Therefore, finding fast and reliable solutions when belt damage occurs is crucial.

This is where AirForm’s products, such as Fix’n Go, PermaFlex, and Belt Repair Tape, come into play. However, these products offer much more than just quick repair solutions. They are also designed to improve the long-term performance of systems.

Belt Repair Tape: Practical and Economical

For temporary repairs, the Belt Repair Tape offers a practical and economical option. Its easy application saves time and provides a temporary solution to the belt. This product helps repair your belt system instantly, while also saving time for permanent solutions.

Fix’n Go: Instant and Permanent

When urgent repairs are needed, Fix’n Go comes into play. This product quickly repairs damage to the belt, allowing production to continue without interruption. Its easy-to-apply design eliminates the need for extended downtime to repair the belt.

PermaFlex: Flexibility and Durability

PermaFlex was developed to adapt to the diverse operating conditions of conveyor belts. This flexible and durable product allows for repairs without damaging the belt structure.

Things to Consider When Choosing a Tape Repair Product

Product Durability: The durability of the belt repair product affects its long-term performance. High-strength products are particularly important in heavy-duty applications where the belt operates under constant tension.

Ease of Application: The application time of the repair product is directly related to production downtime. Fast-drying and easy-to-apply products allow the belt to be restored to working order quickly. For example, products like Fix’n Go, with their quick-installation features, allow for rapid belt repair.

-

- Suitability for the Working Environment: The belt repair product must be compatible with the conditions of the operating environment. This includes features such as temperature resistance and chemical resistance. For example, products like PermaFlex are designed to withstand high temperatures and harsh chemical environments.

- Economic Efficiency: To minimize long-term costs, the belt repair product must be both economical and effective. Products like Belt Repair Tape offer a cost-effective solution, allowing the belt to continue operating temporarily and minimizing interruptions in production processes.

- Safety Standards: Compliance with relevant safety standards is crucial for both operator and product safety. Products with FDA approval or antistatic properties meet these standards and ensure a safe working environment.

Author